The function of ignition systems in gas turbines is supplying energy for gas turbine starting and continuous operation. Therefore,

effective, reliable and fast ignition is very important in starting sequence and continuous operation. Three types of ignition systems are

used in gas turbines; High tension, High Energy(capacitor-discharge) and torch types. Rayan Energy designs and manufactures all three

types of Ignition Systems according to the customer request.

Some of the outstanding features of the Gas Turbine Ignition Systems which Rayan Energy designs and manufactures, are as follow:

• Reliable & Excellent Performance

• Working with both Liquid and Gas fuel

• Integrated and compact

• Resistant to impacts, dust and moisture

• High thermal stability

• Low consumption

• Permanent operation

• Manufactured according to standards such as ATEX Exd

• Long life

• Easy to install and repair

• Customized to application

The Gas Turbine Ignition System has three main parts:

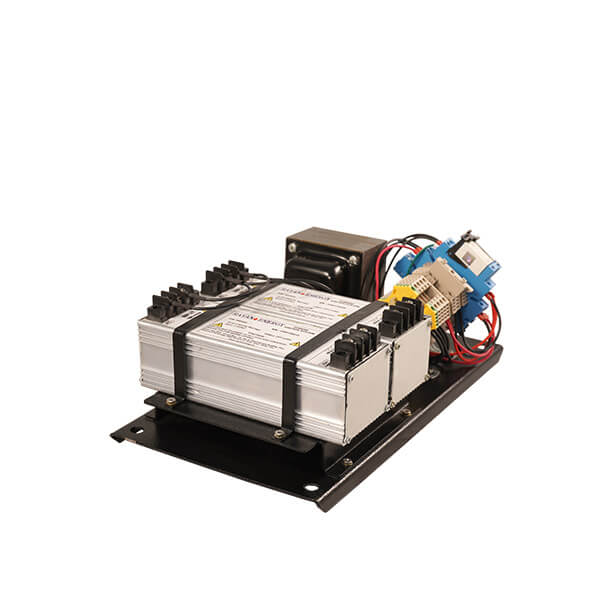

Exciter Box

The exciter box is a device that produce required energy to maintaining spark at the tip of ignitor. Our exciter boxes for gas turbine

ignition systems are designed and manufactured in two main types, AC Input Supply and DC Input Supply. Also, each of these types can

be single or double. Rayan Energy designs and manufactures ignition systems for various applications. It’s our proficiency.

Table of Double Gas Turbine Ignition System properties and specifications

|

Exciter Box |

|

|---|---|

|

Kind of application |

Double Gas Turbine Ignition System |

|

Mounting position ignition burner |

Horizontal / Vertical |

|

Power Supply |

220 VAC +/- 10 VAC / 2 Amp Max |

|

Control Voltage Level |

24 VAC/ 0.5 Amp Max Nominal |

|

Remote Start Relay |

Yes |

|

Power Healthy Feedback |

Yes |

|

Command Received Feedback |

Yes |

|

Energy |

8 j |

|

Output Voltage |

2 KV |

|

Spark Per Second |

5 sps |

|

Operating temperature |

40- °C to °85+C |

|

Protection class |

IP66 |

|

Dimensions L*w*h |

420*320*230 |

|

420*320*230 |

II 2G Ex db IIB+H2 T6, T5, T4 Gb / II 2D Ex tb IIIC, T100' C, T135' C Db |

|

Burning Fuel |

Gas or Liquid Fuel |

Cables

A cable transfers the generated energy by exciter box to igniter. The cables manufactured by Rayan Energy, are compatible with very

harsh conditions such as high voltage, high temperature, acidic and chemical environments. Because of this, we call them high tension

cables.

• Available in different lengths according to customer’s request

• High electrical and thermal resistance

• Protected with armor steel coating

• Flexible

• Suitable for use in all types of Gas Turbine Ignition Systems

|

High Tension Cable |

|

|---|---|

|

Length |

6 Meters (Depend on customer demand) |

|

Connection Size |

M18 |

|

Cable Material |

Conductor Cu+Ag ≥99.99 Insulation Ceramic fire silicone Jacket 1 Silicone Rubber Screen Tinned Copper Wire Braided Screen (Coverage) Jacket 2 Silicone Rubber Screen Fiberglass |

|

Withstands Voltage |

5 KV continuous/ 15 KV Impulse |

|

Withstands temperature |

250 °c |

|

Temperature Resistance |

Till 450 °c in connection parts |

|

Withstand Temperature |

250°C |

Spark Plugs

Spark plug or ignitor is a device in which the spark is generated on its tip. Many types of igniters are manufactured in Rayan Energy. In the

first category, we design and manufacture both rigid and mechanism-based ignitors. The rigid ignitor has fixed parts, so that it should

be in torch or combustion chamber during the gas turbine starting sequence and operation. The mechanism- based ignitor has moving

parts, so that after starting sequence has been completed, the ignitor is pushed out automatically by hot gas pressure. In the second

category, we design and manufacture surface discharge and air gap ignitors. In surface discharge ignitor, a technology named High

Energy is used. In addition to increasing efficiency, this technology reduces the operating voltage of ignition system.

• Liquid and Gas fuel support

• High mechanical and thermal resistance

• High chemical resistance to various gases

• Reliable in high humidity environment

• Working in extreme high humidity environment

• Different OD from 10 mm

• Varity of material

|

Ignition Rod |

|

|---|---|

|

Length |

75 MM |

|

Material |

SS310S (Depend on customer demand) |

|

Technology |

Semiconductor |

|

Discharge Voltage |

1 KV to 5 KV |

|

Burning Fuel |

Gas or Liquid Fuel |

|

Operating temperature |

Continue service to 925 °c |