Flint Burner

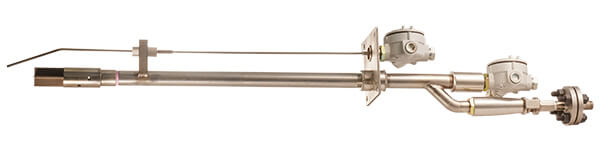

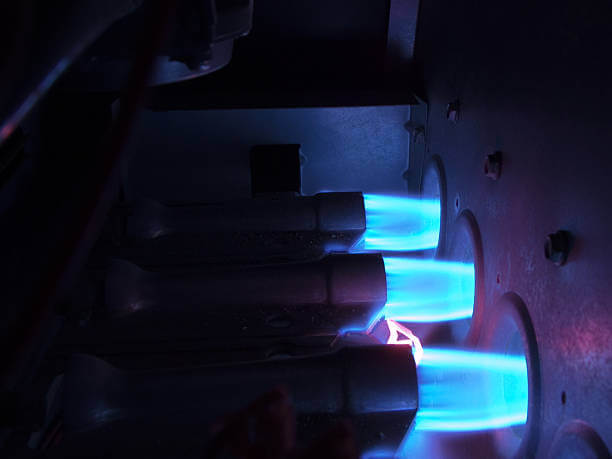

Pilot burners are mainly used to light industrial burners in furnaces, boilers, heaters and incinerators. Rayan Energy Co. manufactures

heavy, moderate and light duty pilots in two types:

• Premixed Gas Pilot Burners (Atmospheric, Induced and Forced Air)

• Non-Premixed Gas Pilot Burners (Atmospheric, Induced and Forced Air)

Some of the outstanding features of the pilots which Rayan Energy Co. designs and manufactures, are as follow:

• High flame stability in different operational conditions:

» Stable flame in pilots is very important and critical for lightening the main burners safely during the commissioning of furnaces especially with dangerous and high reactive feeds like hydrogen.

• Manufactured from high quality materials

• Checked and tested according to ASME, API or DIN standards (depending on customer request)

• Reliable and effective source of ignition for oil and gas burners

• Rayan Energy pilots can be equipped with one ionization rod and two ignition rods to increase the safety and reliability of combustion

systems according to customer request

• Rayan Energy pilots can be used temporarily or permanently according to the application case:

» If there is positive pressure at the main burner opening, it is suggested to use permanent pilots.

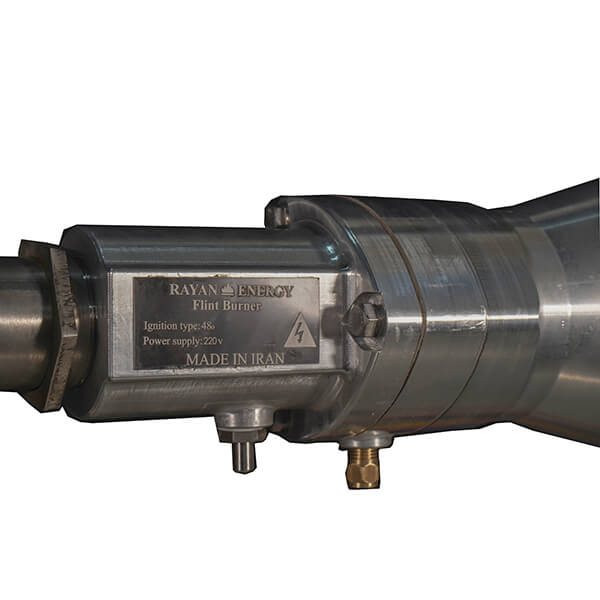

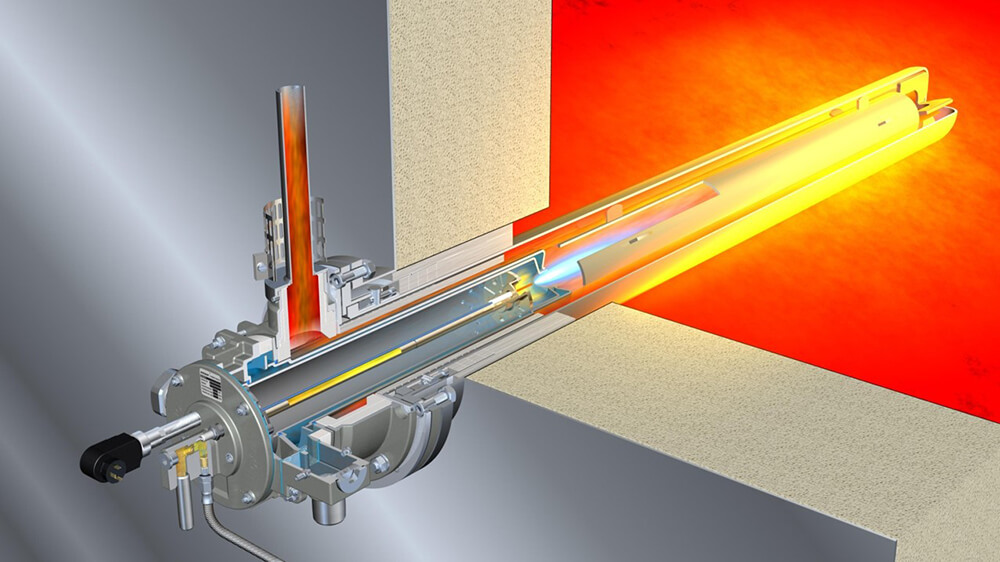

Flint Burner: The Heavy-Duty Pilot Solution

The Flint Burner, expertly crafted by Rayan Energy Co., stands as a premier choice among duct burners for process furnaces and boilers. Designed for heavy-duty applications, it offers unparalleled adaptability and performance.

Key Features:

- Customizable Design: Available in various sizes and capacities to meet specific customer needs and application requirements.

- Stable Flame Operation: Compatible with different air supply modes, including atmospheric, induced, forced, or compressed air.

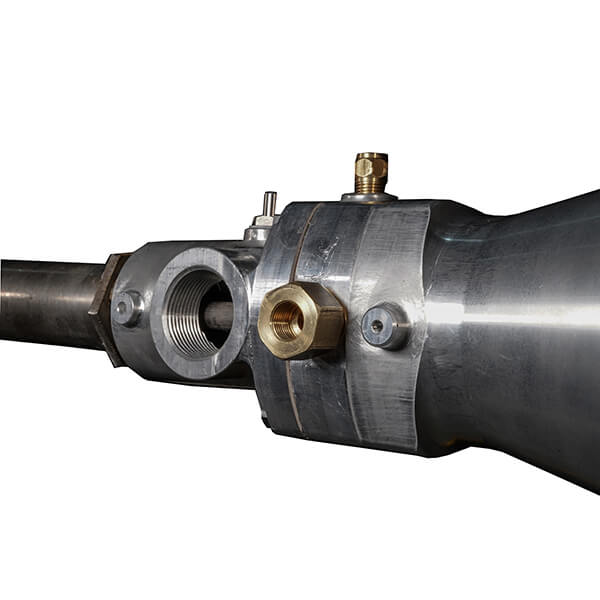

- Advanced Flame Detection: Utilizes an ionization rod for reliable flame presence monitoring.

- Visual Flame Quality Indicator: Features a barograph with multiple LEDs for at-a-glance assessment of flame status.

- Robust Flame Stability: Maintains consistent performance across diverse operational conditions.

- Premium Material Construction: Built from high-quality materials for longevity and resilience.

- Rigorous Testing: Subjected to thorough checks and tests in line with ASME, API, or DIN standards, tailored to customer preferences.

- Flame Generated Feedback: Provides valuable operational insights for system optimization.

For a burner that delivers both reliability and efficiency, choose the Flint Burner by Rayan Energy Co. Contact us to learn more or to discuss your specific requirements.

Ignition Unit | |

|---|---|

Application | Ignition system for main burner in furnaces, boilers and incinerators |

Mounting position | Horizontal/Vertical |

Tube material | Stainless steel 304/316/310L |

Housing material | AL7000 |

Connection parts material | Stainless steel 316 |

Gas fuel | Natural gas, propane, LPG, refinery gas |

Gas pressure | 1.5 – 0.5 bar g. (Natural gas) |

Air supply | Induced, forced or compressed air |

Ambient operating temperature | 40- °C to °65+C |

Protection class | IP65 |

Outer diameter | 48 to 70 mm (other diameters on customer request) |

Length | 400 to 3000 mm (other lengths on customer request) |

Igniter | High energy |

Flame detection system | Ionization (Feed Back contact) |

Gas connection | Standard size: ½” NPT (other sizes on customer request) |

Air connection | G 1 ¼’’ (forced air) or 8/3’’ NPT (compressed air) |

Application | Ignition system for main burner in furnaces, boilers and incinerators |

Control & Ignition Box | |

|---|---|

Function | Continuous Ignition |

Spark Energy | 2 Joules |

Spark Voltage | 10000 VAC |

Spark Frequency | 100 Hz |

Power Supply | 60–50 115 ,230 Hz |

Power Consumption | 25 VA |

Housing Material | AL7000 (Depending on Customer Demand) |

Dimensions l×w×h | 260 mm ×160 mm × 90 mm |

Protection Remote Start Relay Flame Relay | Ip65 Yes Yes |

Max. Cable Length | 10 M (Depending on Customer Demand) |

Explosion Proof | ATEX Ex.d IIB T6 (Technical Report or Certificate Based on EN/IEC 0-60079 And EN/IEC 01-60079) ATEX EU Type (Optional upon Customer Order) |